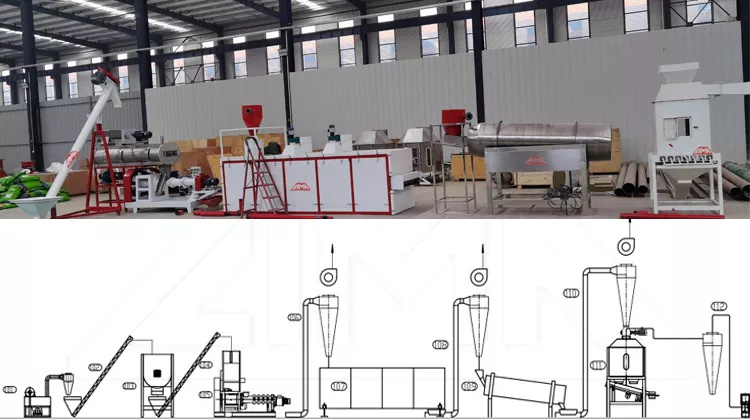

This is a 500-600kg/h production line with wet fish feed pellet machine as the main machine.

Equipment configuration

Mixer → transfer unit → extruder → elevator → dryer → cooler → vibrating screen → elevator → oil spraying machine → automatic packing machine

Crusher:

The crushing process is one of the main processes in a feed factory. The purpose of crushing is to obtain feed suitable for making high-quality feed and most suitable for animal digestion. The crushing quality directly affects the comprehensive cost of feed production quality, output and power consumption, and also affects the inherent quality and feeding effect of feed.

Mixer:

After the materials are crushed and batched, they must be mixed. The mixing uniformity of the mixer is very important in feed processing. It is an important factor that affects the quality of the feed. Therefore, it is very important to choose a suitable mixer in this way.

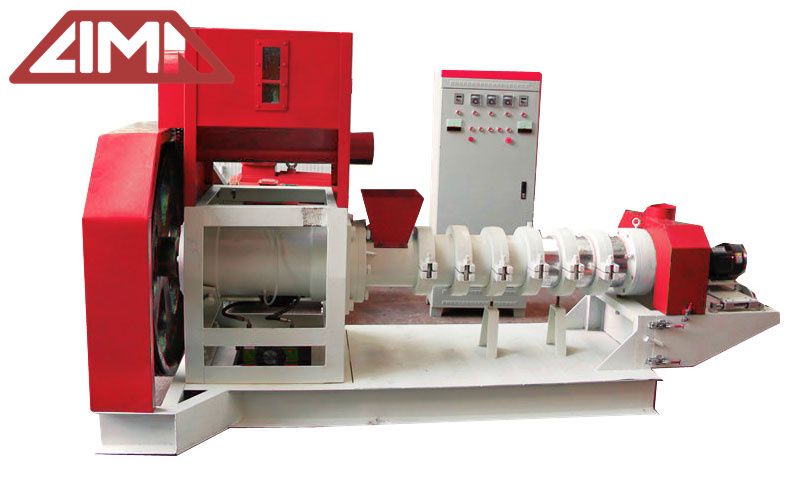

Pellet Machine:

The design of pelleting process is an important factor affecting the quality of aquatic feed. The expansion equipment used in production is mainly a single-screw extrusion expander, which can be divided into dry way and wet way extrusion expanders. Most of the extrusion expansion equipment used today is dry and wet. The extruder can produce floating, sinking, slow sinking feed and semi-moist feed, which can adapt to the feeding requirements of various aquatic animals. And you can come to see the fish feed pellet machine in Lima.

Dryer:

The pellets just produced are wet. In order to better flavor them later, the pellets need to be dried to facilitate storage.

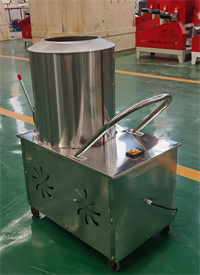

Cooler:

The hot particles after granulation are post-cured and enter the cooler for cooling. Since aquatic pellets have higher requirements for water resistance, the cooling rate should not be too fast to avoid cracks on the pellet surface. The most commonly used cooling equipment is a counterflow cooler, which has a good cooling effect.

Hope you can come to see the fish feed pellet production line in LIMA.