500-600kg Technological procedure:

Mixer → transfer unit → extruder → elevator → dryer → cooler → vibrating screen → elevator → oil spraying machine → automatic packaging machine

Crusher: The crushing process is one of the main processes in a feed factory. The purpose of crushing is to obtain feed suitable for making high-quality feed and most suitable for animal digestion. The crushing quality directly affects the comprehensive cost of feed production quality, output and power consumption, and also affects the inherent quality and feeding effect of feed.

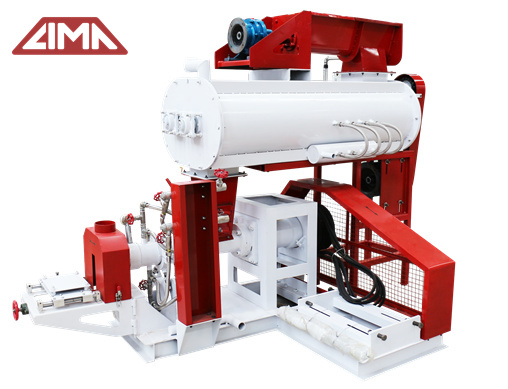

Mixer: After the materials are crushed and batched, they must be mixed. The mixing uniformity of the mixer is very important in feed processing. It is an important factor that affects the quality of the feed. Therefore, it is very important to choose a suitable mixer in this way.

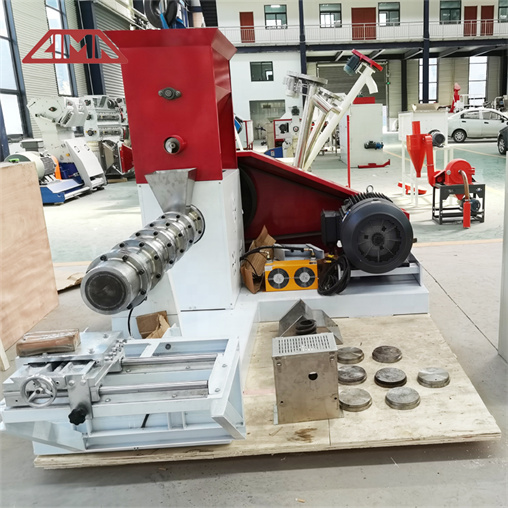

Pellet Machine: The design of pelleting process is an important factor affecting the quality of aquatic feed. The expansion equipment used in production is mainly a single-screw extrusion expander, which can be divided into dry way and wet way extrusion expanders. Most of the extrusion expansion equipment used today is dry and wet. And you can see the fish feed pellet machine, which is so hot in the fish farm.

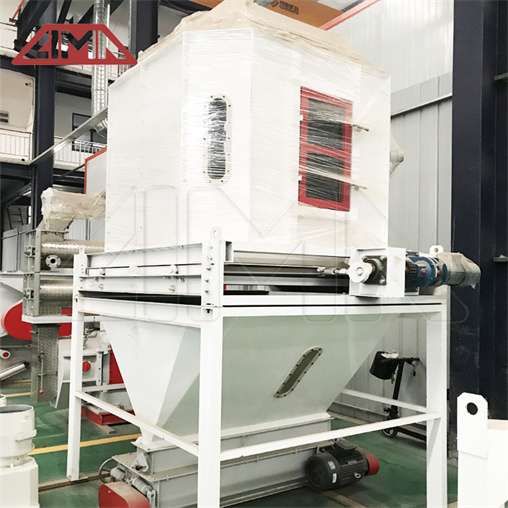

Dryer: The pellets just produced are wet. In order to better flavor them later, the pellets need to be dried to facilitate storage.

Hope you can come to Lima to see the floating fish feed production line.