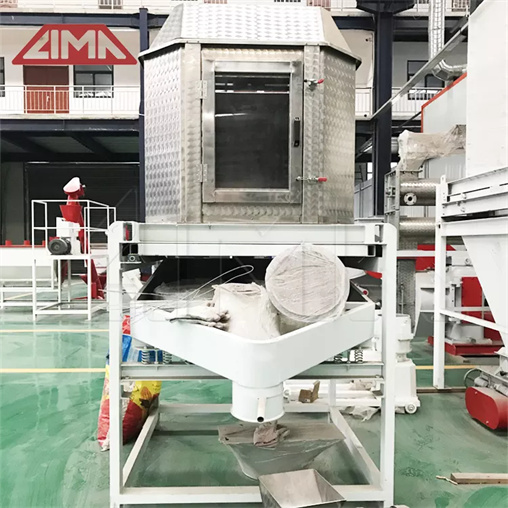

Counter flow cooler machine cooling hot feed pellet in feed production line

Counter flow cooler machine is commonly used equipment in pellet industry to reduce temperature and moisture of processing pellet.

Counter flow cooler machine is commonly used equipment in pellet industry currently with the direction of the air and product of pellets in opposing directions.Pellets will leave the pellet mill at temperatures as high as 190°F and moisture contents are high as 17-18%.

Hot pellets from pellet making machine are still soft and easily broken, which can result in a high percentage of broken and powders.For proper storage and handling of the pellets, their moisture content must be reduced to 10-12% and their temperature to about 15°F above atmospheric temperature. This is to be accomplished by passing a stream of air through a equipment of pellets.The cooling capacity of pellets depends on the size, density, temperature and composition of pellets. The pellets can be harden due to evaporation of water and temperature being reduced to about 5℃ above ambient temperature by cooling.which is economical and convenient for pellet storage and transportation. How about fish pellet machine price.

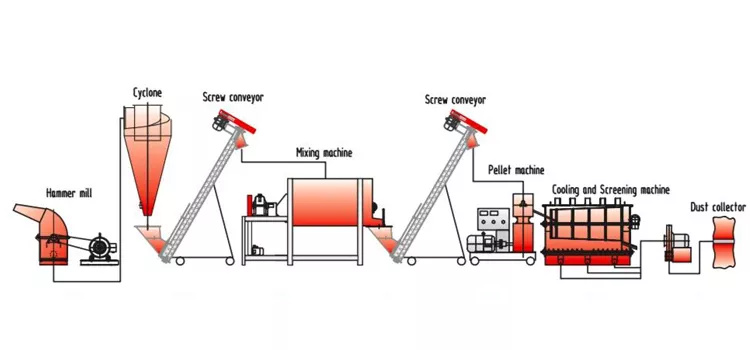

Working Principle of Counter Flow Cooler Machine. There are two processing in cooling system: heat transfer and moisture transfer.

The pellets flow (usually by gravity) from the pellet mill to fill the columns and the hopper above the columns up to the level sensing device near the top of the funnel shaped hopper. Pellets resting in this hopper act as an air seal that forces the cooling air to pass through the column of pellets to reach the fan. The pellets is being cooled in the bin by air flow, which enters the bin through the discharge gate and leaves the bin through the air outlet. Pellets layer height is controlled by a level sensor. The level sensor ensures that the product layer is kept at a predetermined height. As soon as pellets activate the level sensor, the pendulum discharge is operated and pellets are discharged through the hopper. Discharging stops as soon as the product gets below the level sensor.

In order to prevent overflow, the cooler has been provided with an overflow sensor, which stops product supply to the cooler.While the flow of pellets through the columns is being automatically related to exactly the production rate of the pellet mill, the fan is drawing air through the columns of pellets into the air plenum chamber , discharging this feed dust laden air to a cyclone “dust” collector.During a production run, an accumulation of feed dust may build up in the plenum chamber.Therefore, before the next run the dust accumulation should be cleaned out to prevent contamination.

You can come to our website to lean about the floating fish feed production line.

Small Tips: Cooling should be a gradual process. Pellets are cooled too quickly or for too long period, which both can lead to higher abrasion. Moreover, small pellets emit heat and moisture more quickly than large pellets.

Features of Counter Flow Cooler Machine1.Feed pellet cooler machine adopts counter flow cooling principle to cool down pellets without direct contact between cold air and hot materials, thus can avoid the surface cracking of pellets.It can avoid the shock cooling phenomenon when the cold air contacts with the hot material, thus can prevent the pellet appearance generating cracking.

2.Cooling chamber adopts the latest design ,it can ensure cooling with no dead angle,no residual pellet .

3.High cooling speed and favorable cooling effect.The cooled feed pellets temperature is approach ambient temperature,it won’t be higher than 3~5℃ and maintaining optimum pellet quality.

4.Feed pellet cooler machine adopt air-closed material feeder, large inlet air area, outstanding cooling effect.

5.The material discharging device adopts slide valve reciprocating type, stable and reliable running, little residual.

6.Wide application. It can be used to cool various kinds of pellets.Long service time, high automation and low noise.