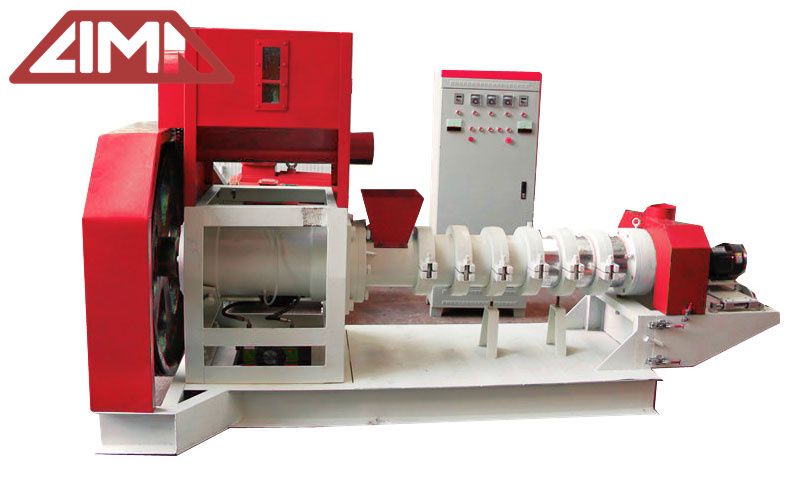

Extruder and floating fish feed processing technology

The extruder is used for the production of feeds for poultry, pets, aquatic products, etc. The output is uniform, the length can be adjusted, and the palatability is good. Among them, the extruder has been upgraded to strengthen the fuselage, increase the reinforcement of the feeding port, have a larger capacity, wear-resistant and durable, and is easy to install and disassemble.

Extruded material production process:

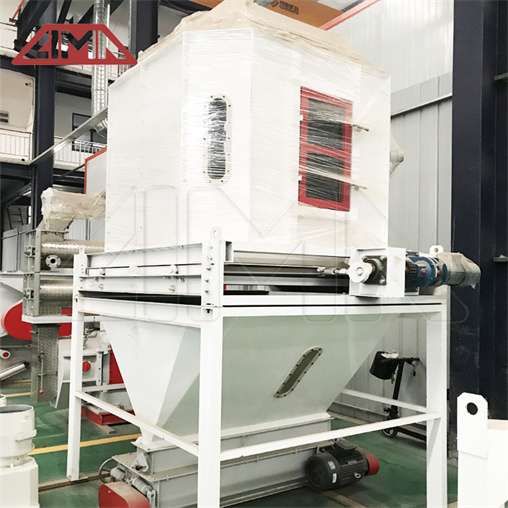

Some heat-sensitive vitamins should be added to the extruded powder. First, steam or water at about 100 °C is added to the powder to make the water content reach 25%, and then the hot powder is passed through the extruder barrel.

Under the pressure of about 140 ℃ and 6 kg/m2, it is sent to the compression molding device, and then the pressure drops rapidly, and the evaporation of super hot water causes the expansion of the particles (granulation).

After the expansion, the grease is immediately sprayed on the surface of the particles to ensure The granulation surface is smooth. At this time, the pellet feed is once again sent to the heating channel to evaporate, reducing its water content to less than 10%, and finally cooled to room temperature to form extruded pellet feed. You can also go to see the fish feed extruder machine.

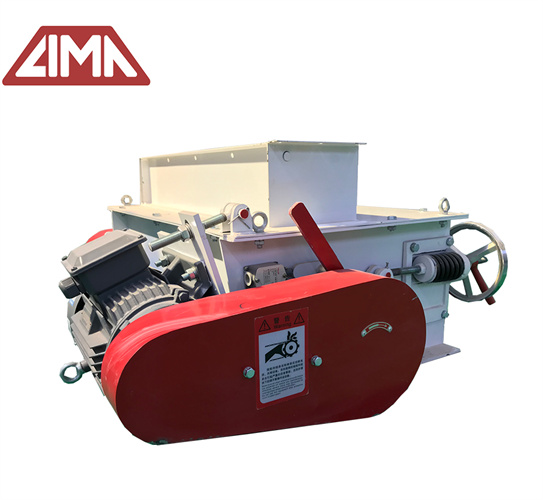

The mineral pre-powder can be added before the raw material is pulverized, and the vitamin pre-powder should be added after the raw material is pulverized and mixed. The purpose of this is to reduce the loss of vitamins during processing and heating. The particle size should generally be 1-2 mm, which is convenient for fish and shrimp to eat, otherwise, it will cause waste due to poor palatability of the feed.

Any questions, you can come to limapoultrymach contact and leave your questions.