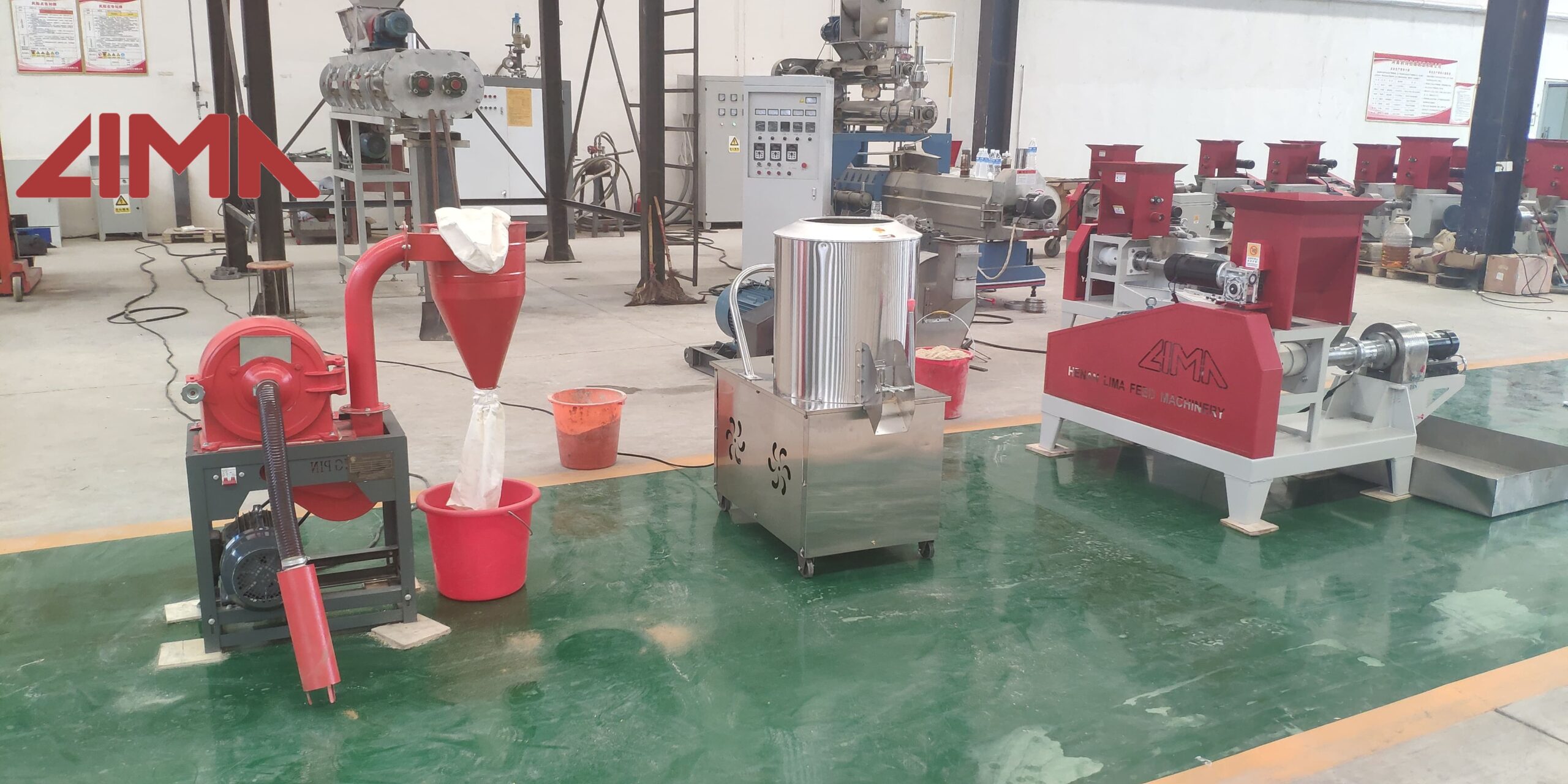

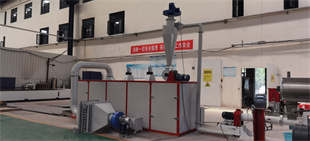

Feed Pellets Machine Production Line Full Automatic Twin Screw Extruder Pet Food Processing Animal Cat India Fish

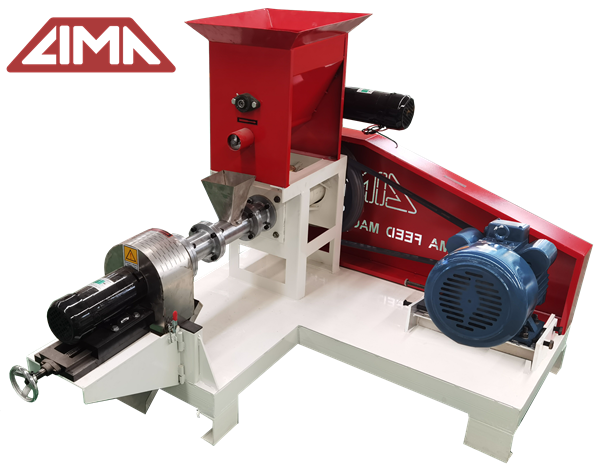

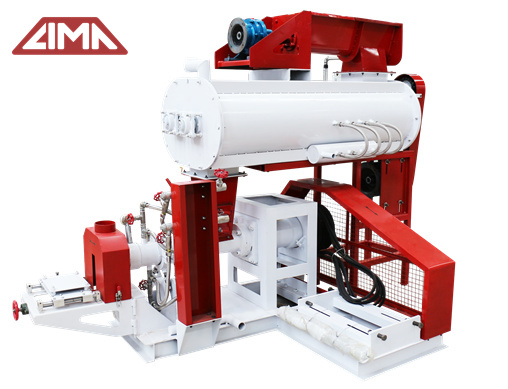

There is no need to heat outside the machine, through the screw extruding of the raw material, heat is produced and gathered during the rotary working process in the airtight environment, and during the high-temperature ripening process, the starch and fiber of the raw material become swell. Then under the pressure-tight condition, the material will be formed into pellets by shaping mold. In the end, through the high pressure produced by the regular rotating of the screw, after being cut by the forepart cutter which rotates regularly and high-speedily, the finished products will be shrunk and become small average puffed balls in room temperature and pressure.

Applicable Industries:Manufacturing Plant, Farms

After Warranty Service:Video technical support, Online support, Spare parts

Local Service?Location:Nigeria

Showroom Location:Nigeria

Condition:New

Place of Origin:Henan, China

Brand Name:LIMA

Type:Feed Pellet Machine

Voltage:220V/380V

Dimension(L*W*H):2100*1450*1350

Weight:1860kg

Certification:ISO9001/CE

Warranty:1 Year

After-sales Service Provided:Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

Key Selling Points:Multifunctional

Marketing Type:Ordinary Product

Machinery Test Report:Provided

Video outgoing-inspection:Provided

Warranty of core components:1 Year

Core Components:Motor, Engine

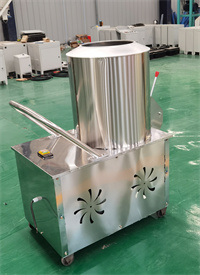

Name:pellet making machine

Application:Poultry Farm

Raw material:Wheat Bran

Capacity:300-500kg/h

Color:Clients’ Requirement

Function:Producing Animal Feeds Pellets

Material:Iron

Motor:Chinese Brand

Product name:Animal Feed Pellet Plant

Usage:Animal Poultry Livestock Pellet Making Machine