Floating fish feed production line,small scale fish food production plant

Floating fish feed production line is applicable to fish farms, fish feed manufacturers and pet food factories,this plant can produce floating and sinking fish feed and pet food, like catfish,tilapia,shrimp,trout, turbot, cod, halibut, yellow tail, sea bass, sea bream etc.

Lima brand fish food production plant adopt fully automatic extruding process, automatically microcomputer steam added technology, it can control of the sinking and floating material precisely, better control the degree of maturation, it can improve the ripening degree which increase digestion and absorption rate for aqua animals.Steam cooking and curing molding extrusion process, pre-conditioner and final conditioner process altogether determine the characteristics of the final product.

The floating fish feed production line produce high-energy fish feed efficiently, with a precise balance of proteins, oils and carbohydrates, processed for optimum digestibility with reduced waste. Our systems produce the right formula that turn ” feed into flesh” and is particularly suited for processing a wide selection of recipes and raw materials. Lima feed machinery processes also accurately control pellet density for specific product attributes, such as sinking or floating properties. The user can manufacture a wide range of products that are adapted to the nutritional requirements of the animals, when required, and feed dimensions perfectly calibrated from 0.5~10 mm. With Lima fish food production plant, customers can minimize costs while ensure optimal product quality and maximize revenue. Meanwhile, customer can produce ideal feed of maximum digestibility and feed conversion ratio, so the overall health is guaranteed. Lima pellet machine leading aquatic animals (fish, shrimp, crab, etc.) feed production line solutions meet customer’s individual line from 0.5 to 5 tons per hour production needs. Lima technology also complies with the toughest environmental and quality requirements, maintaining water quality and breeding healthy animals, which in turn generates improved conversion ratios.

How to Make Fish Feed Pellets?

A complete fish feed pellet production line should includes the following process:

Material Crushing→Material Mixing→Pellet Extruding→Pellets Drying→Oil Spraying→Pellets Cooling→Pellet Packing

Maybe you should learn about the feed production line.

1.Materials Crushing

Animal Feed Crusher MachineIn order to accelerate mixing process and increase nutritional utilization, people need to grind raw materials into powder, which always requires a crushing machine ¨C Hammer mill crusher. In the meantime, the powder sizes of materials have great effect on feed size and quality in the pelleting process, the powder with smaller size will be much better for the pellet process.

2.Materials Mixing

Animal Feed Mixer Machine The daily intake of fish is very small, hence, to ensure fish can get complete nutrition from daily feed, the feed ingredients should be mixed uniformly after grinding. It’s very important to use high mixing degree of blender because it can influence the quality of fish feed. Our production line has matched well-designed fish feed mixer for equably blending powder or particle materials with good flow ability.

3.Pellet Extruding

Fish Feed Pellet MachineOur fish feed pellet machine is able to produce high quality feed pellets for fish and also for pets like dogs and cats. Moreover, it is not hard to produce feed pellets with different diameters (usually from 0.9mm to 15mm), just changing the size of pellet mill die mold, which gives fish farmers more flexible choice according to fish type and growth situation. The Pellet machine is the key equipment of whole production line, the user can choose it according to their investment cost, production scale, and feeding characteristics and habits of different aquatic animals.

4. Pellet Drying

Feed Pellet Dryer Machine Produced fish feed pellets are in high temperature and high moisture content, so fish feed pellets dryer is needed to dry pellets, which can reduce pellet moisture rapidly. Feed pellet dryer is ideal equipment for pellet drying.

5.Oil Spraying

Oil Sprayer MachineThe good taste and nice smell will attractive fish for more intake. This oil sprayer machine rotates with high speed, spraying atomized oil on both surfaces of the fish feed pellets. It will produce flavoured fish feed pellet and the oil will prevent moisture absorption, excess oil during this process is then recycled through a special filter.

6.Pellets Cooling

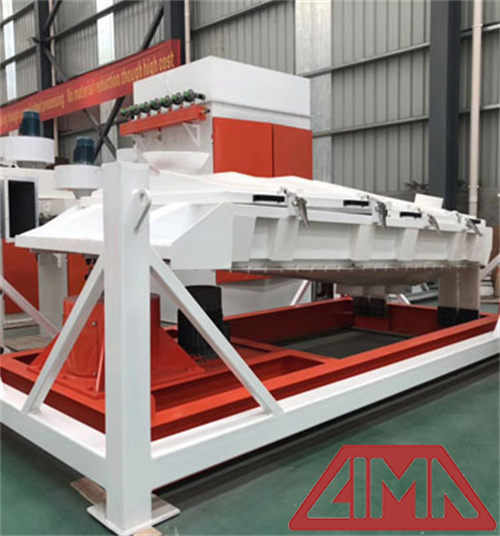

Pellet Cooling MachineWhen the pellet temperature high, they become soft, and can easily break. We need cool feed pellets and make it hard. The cooling type adopted by most fish pellet production plants is the counter flow cooler .

7.Fish Feed Pellet Packing

Automatic Weighing and Packing MachineAutomatic weighing and packing machine can weigh and pack fish feed pellet machine in to bag ,for pellet store, transport, and sell on the market. It can also prevent feed deterioration and thus prolong its shelf life.

How to choose a good quality fish feed production line?

How to get complete fish feed production process technology program?

To make pellets easy to store, transport and sell, they should be packed properly. Pellets weighing and packing can be finished at the same time. Moreover, the manufacturer also need prevent feed deterioration and thus prolong its shelf life. Automatic fish feed production can largely reduce labor cost and increase working efficiency. Manufacturers are keeping exploring more advanced production technology and fish feed production line to satisfy customers¡¯ increasing demands for high-quality and nutritionally-balanced sinking & floating fish feed.

It lies in the production process. As technology and market leader in the industry, Lima pellet machine knows that in aquatic feed production process, in addition to reasonable formula, a very important point is that the process must be gentle to prolong the feed in the water-soluble, which is very important to aquatic animal health and growth. We have the most experienced design engineers, reasonable recommendation, diversified technology fish food production plant design.

Come to see the fish feed extruder machine in Lima.