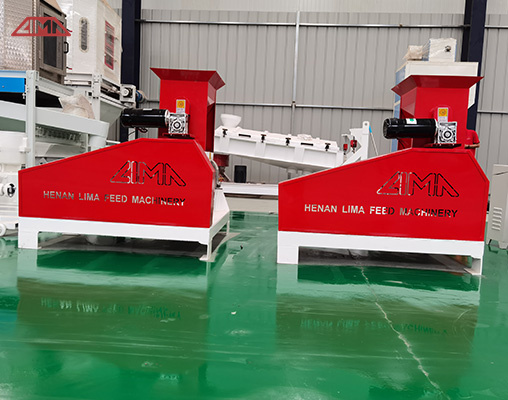

Good price of floating fish feed pellet machine in wet type

Fish feed extruder in wet type is widely used to produce various pets such as fish, catfish, shrimp, cat, dog and other aquatic feed pellets. The grain raw materials used in the fish feed extruder such as wheat, soybean, cake and other residues, etc., the extruded particles can float on the water surface without dissolving for more than 24 hours. Fish feed extruders are mainly used in medium or large feed processing plants and aquaculture farms. For mass production of feed pellets, fish feed extruder are ideal!

Why is the price of wet type fish feed pellet machine more expensive than ordinary fish feed pellet machine?

Compared with floating fish machine in wet type, ordinary fish feed pellet machine have lower capacity and are more popular with small and medium-sized manufacturers and farmers.

The reasons why the fish feed pellet machine in wet type is more expensive than the ordinary fish feed pellet machine are as follows:

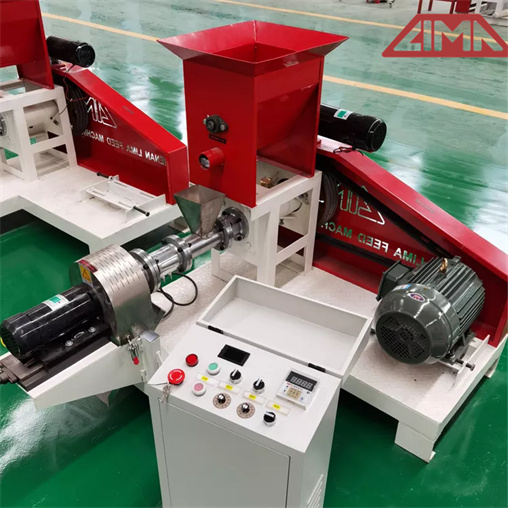

1. The floating fish feed machine in wet type needs to be used in conjunction with the boiler. The boiler continuously provides hot steam to the conditioner, so it can fully cook the material and improve the nutritional value. Greatly improve the quality and quantity of particles with reduced power consumption.

2. The key components are vacuum quenched, with higher machining accuracy and longer service life.

3. The manufacturing process of the machine is more complicated. The spiral sleeve adopts a jacket structure, which can inject hot steam or cooling water to effectively control the puffing temperature.