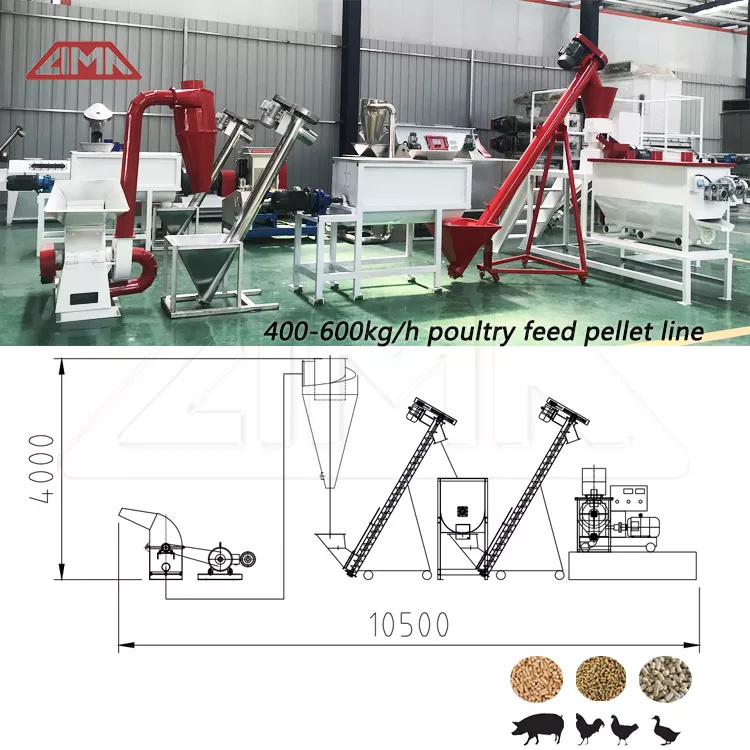

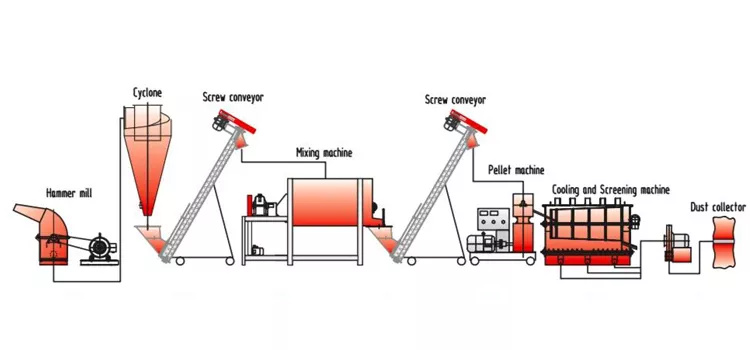

Hammer mill grinder machine,industrial feed grinding machine

Lima series hammer mill grinder machine is universal type product with stable performance.It is widely used in medium and large scale feed production line , chemical and biological industry for raw material grinding, such as corn, sorghum, rice, soybean, wheat, and grain grinding, especially suitable for the baby pig, fish feed, poultry and livestock feed production. Double attack technology enhances its crushing effect. Advanced feeding and discharging devices make the production more convenient.

Reasonable base design steady its whole body; Components welded with international standard steel plates improve its mechanical strength and lengthen its lifetime.The special water-drop design of feed hammer mill can ensure a larger space for grinding chamber and improves working efficiency by 40%.

Application of Hammer Mill Grinder Machine

1.Animal husbandry. Hammer mill grinder machine can be used as a pretreatment tool for the production of animal bedding and feeding stuff. It can crusher series feed raw materials like dry yam, peanut, rice and other plants, husks, maize, wheat, beans of all grain with large capacity.

2.Agricultural industry. Industrial feed grinding machine can be used for the production of fertilizer, pellet fuels etc.Nowadays pellet fuels are now widely applied in many factories. The raw materials need to be crushed before pellet because wood pellet mill requires its feedstock to be less than 6mm. Therefore, before further processing, hammer mill grinder machine is necessary equipment.

3.Recycle industrial. Recycling reduces the costs you would otherwise incur disposing of unused materials and byproducts. It can be widely used in crushing all kinds of straws,cotton straws,wood, weed, PVC foam board,rubber, etc.

Features of Industrial Feed Grinding Machine

1.Hammer mill grinder machine is used to both of coarse grinding and fine grinding.Which is applicable in large and medium scale feed factory, alcohol factory, feedstuff factory, bio energy factory etc.

2.The crushing room is designed as water drop figure. With adjustable hammer screen space and optimized arrange of hammer pieces, it can fully to meet the coarse and fire crushing requirements.

3.It adopted speed governing feeder, feeder with belt transport or self scavenging impeller feeder.

4.Tested by the high precision balancing machine, the hammer mill won’t move a bit when it run, which reduces

noise and prolongs motor bearing’s life.

5.The feed grinding machine adopting international advanced technology, Improvement on structure and the chosen material of wear-resistance hammer, increasing crushing efficiency 20%.the output can be increased by 25%.

6. The bottom of crushing chamber is fitted with U-shape double grinding structure, further improving the capacity with evener particle size.

Capacity of Hammer Mill Grinder MachineThe capacity of feed grinder machine depends upon several factors.

¡ô Raw material variety influences the performance of this machine to a greater degree than any other factors.Hammer mill working should be the case:all of the energy consumed in the crushing chamber is delivered by free-swinging hammers, and it is to be expected that there would be a considerable difference in the effect of these impact blows upon materials of varying physical structure.

¡ô Final size of raw materials affects capacity. For example, suppose we were operating a medium-size hammer mill on corn, turning out a 40 mesh product,the output will be much larger than 60 mesh powder.

¡ôHigher speeds will of course produce better shattering effect to take care of raw materials, but there are definite limits .Thus, in any given machine, the number of rows of hammers used will affect capacity.

Welcome to see the lima feed machine.