How to Produce Floating Fish Feed

After choosing suitable formulation for floating fish feed, the next crucial thing is mastering the production process of floating fish feed. And to produce fish feed, there must be several steps:grinding, mixing, pelleting, extruding, drying and cooling.

Mixing & grinding: The main raw materials of floating fish feed should be mixed and crushed before make pellets, so LIMA recommends the related professional equipment- fish feed mixer and fish feed crusher, aiming at producing high quality floating feed with good water stability that is suitable for fish digestion.After weighting the raw materials according to the weight ratio in the formula, and fish farmers would grind the raw materials into 60-100 mesh by using droplet fish feed crusher, then adding other ingredients for uniform blending by using fish feed mixer. Grinding is helpful to increase the exposed surface area of the material, improve the uniformity of mixing and make feedstuff easier to digest, which is very important for small feed intake animals, just like fish. Moreover, mixing and crushing feedstuff also contribute to granulation and extrusion as well. And you can come to lima to see the animal feed mixing machine.

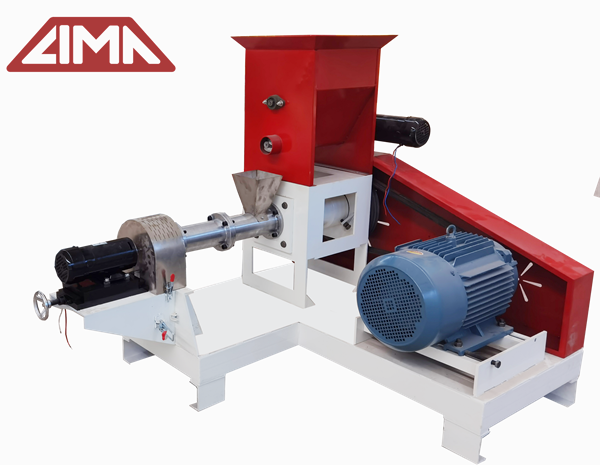

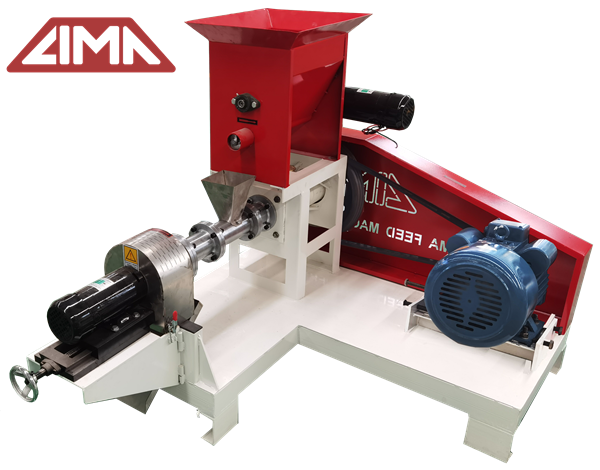

Pelleting & Extruding: During the extrusion process, the heat is generated by the raw material under the action of mechanical energy through the screw, the shear plate and the inner wall of the expansion chamber.Materials actually go through the fusion under the high temperature and high pressure, extruding from fish feed extruder machine, achieving volume expansion due to the pressure reducing suddenly. Customers can choose extruder with various die hole sizes according to their actual requirements because lima is able to provide fish feed extruder machine with sizes from 0.9mm to 12mm, suitable for the different growth. The feed extruder machine in lima is popular.

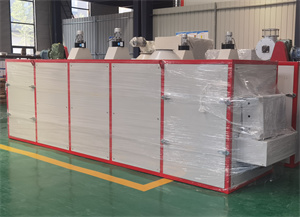

Drying & Cooling: Floating fish feed would be of necessity pellet with high moisture content when it leaves the pelleting die. In case of pellets sticky, farmers also would need specialized and improved drying equipment after they are capable of making floating feed. After drying and cooling, the feed can be stored in a dry ventilated chamber to maintain quality. Using fish feed dryer/cooler makes the feed easier to store, which also makes drying/cooling important parts of feed processing.