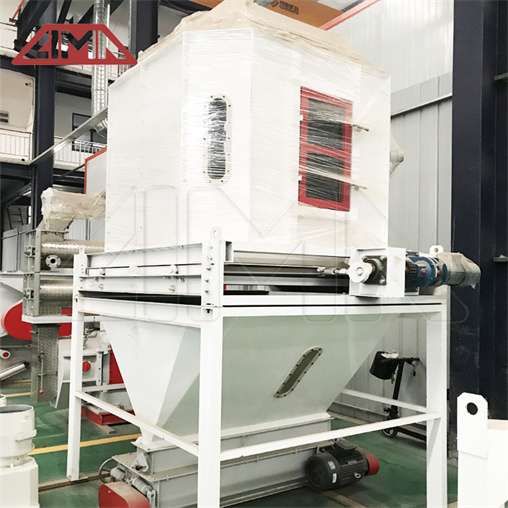

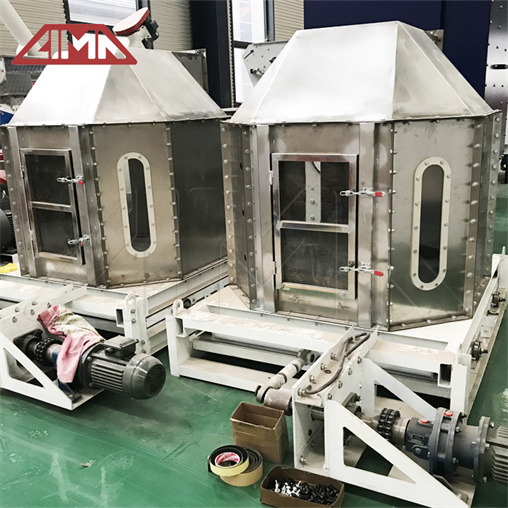

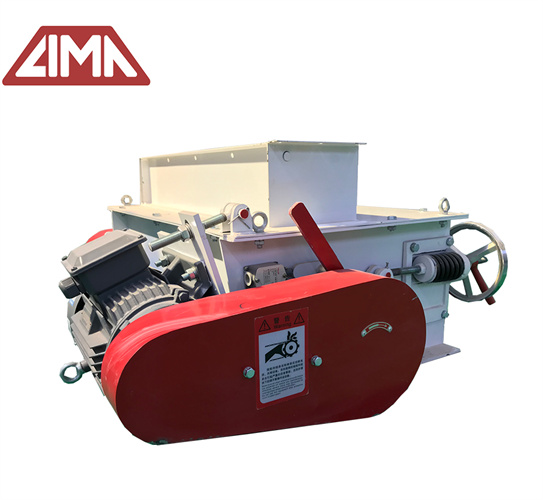

The cooling of the SH series counter flow cooler pellets is an indispensable process in the granulation section. It is the process of removing heat. As we know, heat and moisture are added during the quenching process, and heat is generated through the granulation process and the puffing process.

However, the granulation process requires a certain amount of moisture in order to keep the finished granules stored for a long time and protect them from fungi.

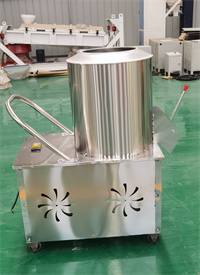

We must remove excess heat and moisture from the particles. Therefore, a counterflow cooler is required to cool.After cooling, the finished product temperature is not higher than room temperature + 3°C ~ 5 ° C, suitable for cooling of granular materials.

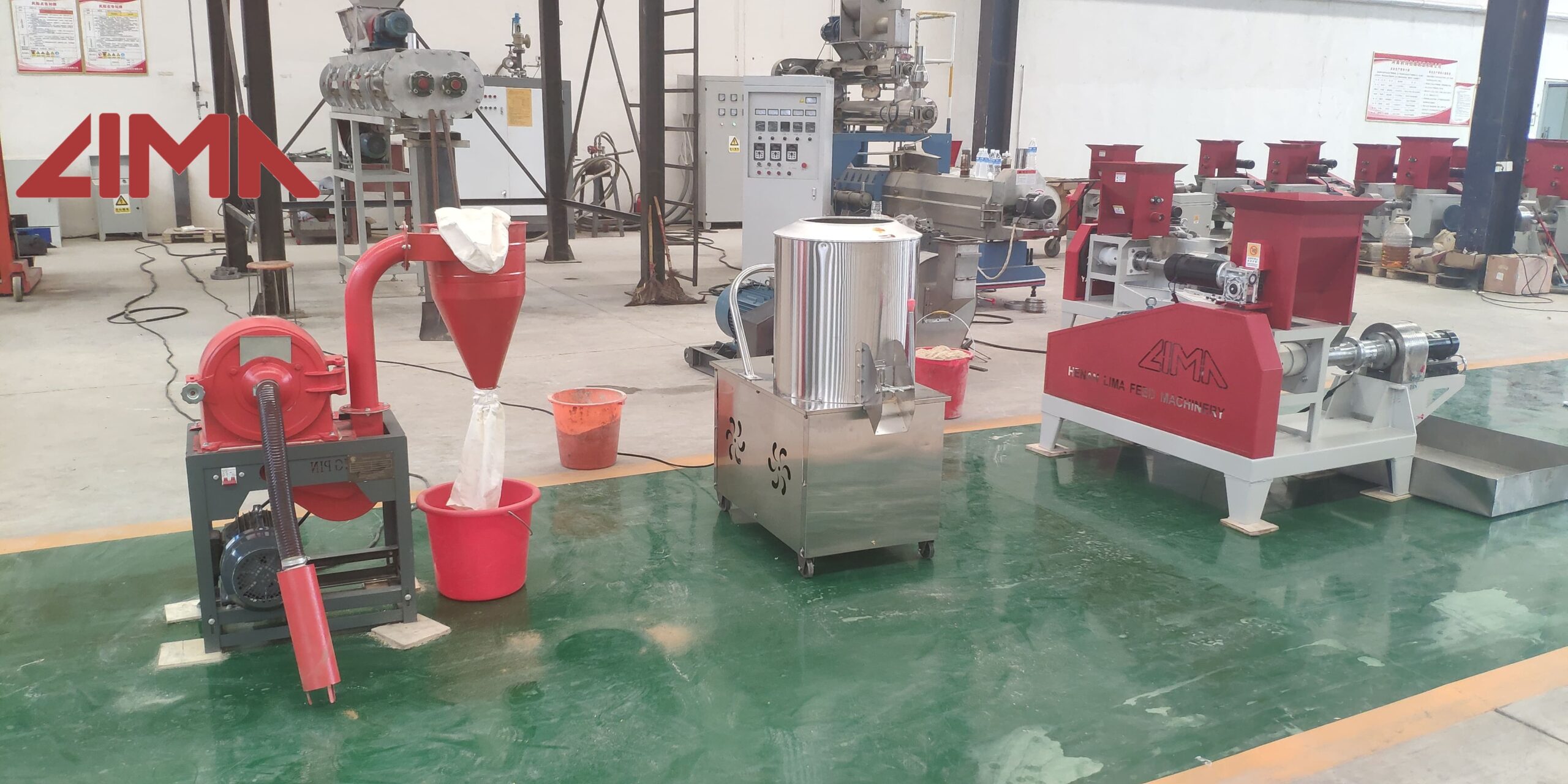

Welcome to see lima feed machines.