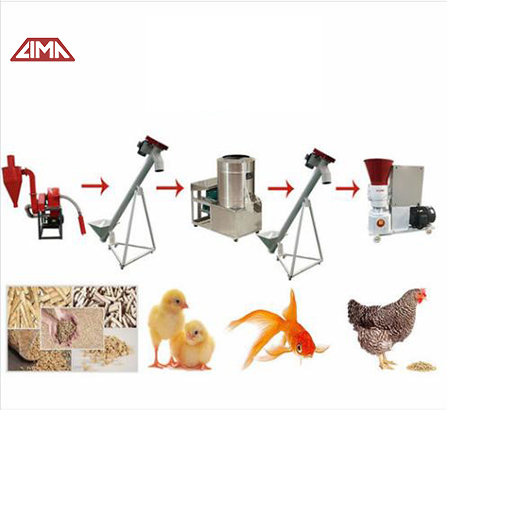

Premix feed plant,mash feed plant for chicken,layer,duck

Premix feed plant can be used to produce chicken premixes, duck premixes, pig premixes, cattle premixes, additive premixes, etc. Premix feed is the brief name of additive premixed feed. It is proportioned with various kinds of micro elements, include all kinds of micro mineral element, Synthetic amino acid, vitamins, some medicine and some other additives, etc.and then evenly mixed with carriers into intermediate type feed products.Premix is an important part of full-price compound feed. It is also a key part to improve the quality of feed products. It plays a role in supplementing and balancing nutrients and promoting, increasing production and preventing disease.Our premix feed plant is based on customer demand, can fully meet the needs of the need.

Features of Premix Feed Plant

The mash feed plant adopted high precision micro-component proportioning system, ensuring that the ingredients of various trace elements, measurement precision. Customers can add a variety of trace elements, drugs, improve animal disease prevention, disease resistance.

Dedicated equipped with efficient feed mixer machine, high mixing speed, mixing uniformity, low residue, CV ¡Ü 1%, which can ensuring mixing precision.

Professional premix production, one large and one small mixer using process configuration, we recommend rationalize production according to customer’s premix varieties,which can reducing energy waste and production costs.

All materials using a dedicated bin with strict procedures, preventing cross-contamination of ingredients;

After blending , the material is conveyed by positive pressure pneumatic, abandoning the traditional mechanical transmission, greatly reducing the residual refuse cross-contamination, which contributes to clean, hygienic and safe transport effects;

Effective and reasonable dust removal system, all the material inlet and outlet are equipped with centralized dust pulses, it’s reducing dust pollution and dust will be strictly controlled by the standard.

Processing Steps of Premix Feed PlantThe mash feed plant mainly consists of raw material receiving and cleaning systems, crushing systems, batching and mixing systems, and finished packaging systems.

Raw Material Receiving and Cleaning

This raw materials cleaning process is separated into granules materials cleaning and powder materials cleaning.

It’s mainly to remove impurity from raw materials, like big impurities, like ropes, soil blocks, cobs and other non-magnetic impurities like iron nails, etc. The cleaning effect to make sure of the quality of final product and machining safety.

Raw Materials Crushing

Raw materials are crushed by the hammer mill crusher. The raw materials are smashed under the high-speed rotation of hammers once feeding into the crushing chamber. With the high pressure and rapid-moving of airflow, the smashed raw materials are further reduced into particle size or very small pieces for further processing.

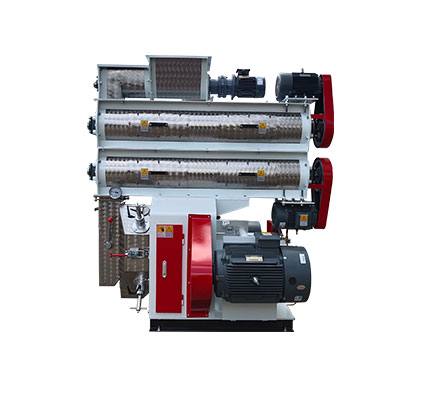

Batching and Mixing

Mixing is a kind of operation in which all kinds of feed materials are mixed with each other under the action of external forces after metering ingredients. The ingredients are weighed using a specific scale accurately, different materials will be added according to different animal nutrition requirements. The automatic premix feed plant adopts one or two batching scales in the batching section, four or six carrier bins weigh separately, and eight small bins weigh separately, among which the micro elements are added manually and equipped with inspection scales. The material ingredients are mixed into the mixing machine and then directly into the finished product bins.

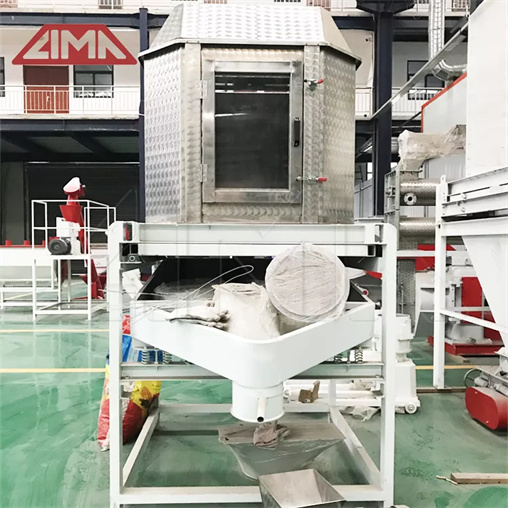

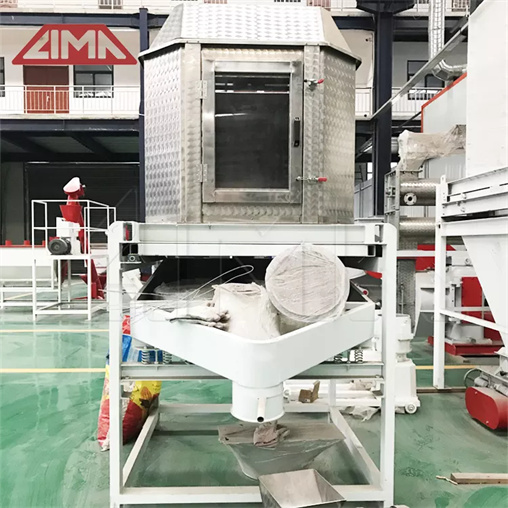

Feed Packing

The finished premix feed after mixed, directly dropped into the finished product bins, and then feeded into the buffer bins of packaging scales through the airclosed feeder, finally weighed by automatic packing scale.

Auxiliary Equipment

The mash feed plant is equipped with dedusting system in dumping hopper and bagging site. We normally match pulse dust collector to make sure the plant is clean without dust, which can to improve the workers¡¯ working environment.

So do you interest in the chicken feed pellet machine? So welcome to lima for a look.