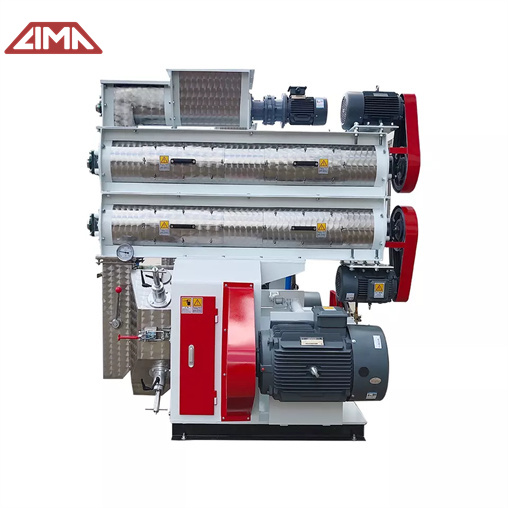

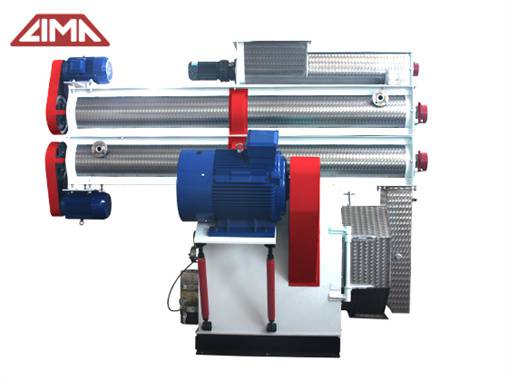

Ring die feed pellet machine of 1 ton per hour

The multifunctional ring die feed pellet making machine can be used to make chicken, duck, goose and other poultry feed, and can also be used to make sheep, cattle and other animal feed. The output of the ring die feed pellet machine is larger than that of the flat die feed pellet machine, and it is mainly recommended for large feed manufacturers.

The capacity of the ring die feed pellet machine in the picture is 1t/h. Suitable for who wants to begin your feed making business.

What the price of one ring die feed pellet machine?

What is the operating principle of the ring die pellet mill, one of the main pieces of equipment in the pellet feed manufacturing line? How much does it cost?

Four processes take feed from the powder stage to the granule-forming state:

1. The speed-regulating feeding auger is used to feed the material into the modulator. After adding hot steam for conditioning, the chute-shaped feeding pipe enters the ring die cover. With the aid of gravity and the centrifugal force created by the rotation of the ring die, the material is tightly attached to the ring die cover and the inner wall of the mold (feeding area) in order to obtain a good granulation benefit (increase the output and quality).

2.As a result of the moving knife, the material is fed evenly and continuously, and the wedge-shaped space (pressing area) formed by each pressing roller and the ring die.

3. Because the gap between the working surface of the outer wall of the pressure roller and the working surface of the inner diameter of the ring die is only 0.1-0.3mm, and this gap is basically horizontal, a certain extrusion force (extrusion zone) is formed.

4. Due to the feeding of the material, under the strong extrusion between the die and the roller, the material is compacted, extruded into the die hole, and formed into a (forming area) in the die hole.

The material is continuously fed into the pressing zone, then extruded into shape, continuously extruded from the die hole, and cut into various required particle lengths by a cutter with an adjustable distance between the knife edge and the outer wall of the ring die.

How much is the price of the ring die feed pellet machine?

The price of the ring die feed pellet machine is affected by many aspects, such as the output, the higher the output, the higher the price of the machine. Another example is the process, the wet process is more expensive than the ordinary dry process. Therefore, if you want to know more about the ring die feed pellet machine, you can get in touch with Lima, we have professional engineers and sales managers who can provide you with professional advice.