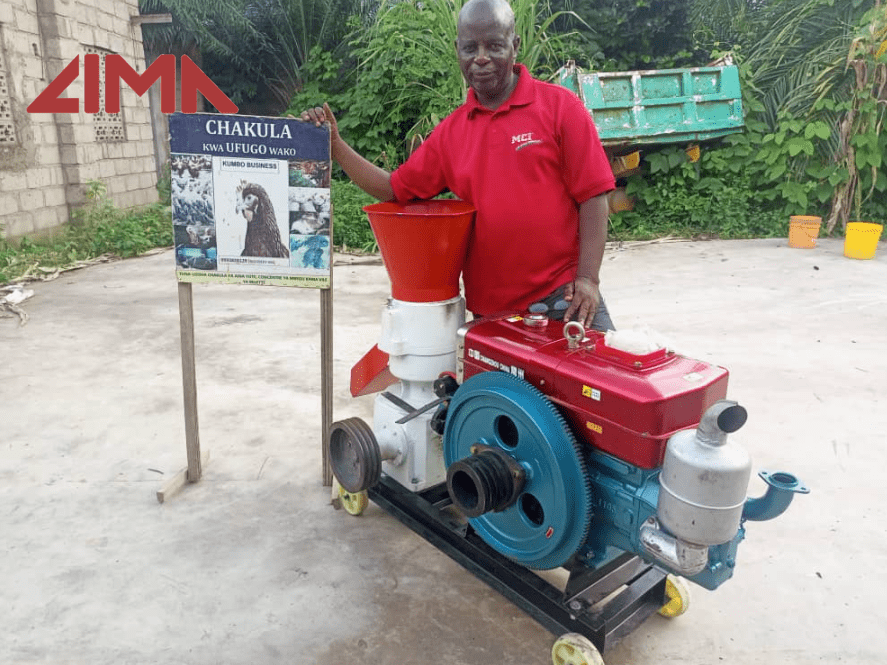

Small feed pellet mill for sale,home pellet making machine price

Small feed pellet mill is small scale pellet making machine that is designed for small feed pellet production. It is widely used by people who breed animals or people who own feed pellet production line for business. The animal feed pellet industry has developed fast in recent years, the technology of feed pellet mill has been mature and advanced, the produced pellets are a balanced combination of different kinds of nutrition for the better growth of poultry, livestock, and other animals. Raw materials can be maize/corn, soybean cake/ powder, wheat bran, bone powder, alfalfa powder, grass, corn stalk, grain, fish powder, and other nutrition additives.

Why do we need feed pellet mill? Whether it¡s your own poultry farming or a large livestock farm, you would know that will costs manpower, materials and finances, especially on feeding thousands of animals like livestock, poultry. With the development of animal feed mill technology,it will be easy to producing your own feed pellets with pellet making machine, you can save a sum of money on purchasing the made-up feed pellets, and you can adjust make feed pellets according to animal growth need, which combine together all the nutritional ingredients, also prevent picky animals, in order to maximize the economic benefits. Some farmers build the complete feed mill plant to reduce the feed pellet cost, they also can sell feed pellet on the market.

What¡¯s the advantage of pellet feed? Livestock feed pellets are a kind of compound feed and mainly made from various raw materials such as grain, cereal, oleaginous crops seed and grass, forage, dried beet pulp, etc, the user can add addictive according to livestock growth such as vitamins, minerals, chemical preservatives and other essential micro-ingredients by cattle feed pellet making machine.

In the eighties livestock researchers found that cows consumed the pelleted feed more rapidly than other forms of feed. Compared with traditional livestock feed like coarse mix, crumbles and meal, feed pellets show more advantages. Livestock feed pellets are formulated according to the type of livestock, like cattle, goats, horses, etc, it can satisfy the nutritional need of livestock and help farmer to gain livestock weight fast, also produce more milk than traditional chopped straw feed.

According to research, undigested chopped straw can stack in the livestock¡¯s stomach and caused livestock tumors and indigestion diseases. But the livestock feed pellets are with no such problems, and they contain more nutrition. Pelleted type of feed can be digested well and improve the performance of cattle.

The livestock feed pellets are in high energy and balanced for protein, vitamins and minerals. For different livestock feed pellets are suitable for bulls, cows, heifers, goat, and sheep, with different ingredients and nutrition. It not only improves the cattle performance but also improves the ratio of feed pellets conversion.

Features of home pellet making machine1.Reasonable and scientific structure, it can both be used by farm owners who want to make feed pellets for sale,it also can be matched for whole production line.

2. The pelleting process enables the grain, legume trypsin boycott factor degeneration, it can reduce adverse effects on the digestion, also kill the parasite eggs and other pathogenic microorganisms, reducing the variety of parasitic diseases and digestive tract system diseases for livestock and poultry.

3. The pellet size has various choices by changing the mold, like 3,4,5,6,7,8mm or other customized diameter, you can customize the flat die according to different materials and realize best pelleting result.

4. The roller and main shaft bearings of small feed pellet mill adopt whole sealing design to ensure no leakage pollution from bearing and lubricating oil. The bearing service life is longer than normal type, which also saves the maintaining time in daily working.

5. The whole machine is casted one. The service life of roller and die can reach 800 hours.

6. Easy to operate and maintain, small area covering, low noise, safe to use, no special requirements for working site.