Pelleted feed: feed pellet size is important

Pelleted feed is considered to have a very significant impact on animal growth and feed intake. The positive effects of pelleting are well documented: higher feed density, no feed ingredient separation, better bacteriological quality, easier ingestion, improved growth.

Compared with mash, pellets enhance bird performance by decreasing feed wastage, alleviating selective feeding, destroying pathogens, improving palatability and increasing nutrient digestibility. The animal fed pelleted diets have higher BW and improved feed conversion than those fed mash feed.

Today, commercial feed production plants are producing different forms of animal feed at different ages. Feed particle size is an often-overlooked aspect of poultry production. Producers should not assume that feed is of uniform size and homogeneously mixed, or that the feed mill is providing the ideal mix of particles in a ration. Feed particles range in size from very fine to coarse, and different grinding methods will result in different particle size distributions. Differences in particle size within a ration can affect both the digestive system and the performance of the bird, even if the overall nutrient values are similar.

Why feed pellet size is important?

Animal select feed particles in accordance with the size of their oral cavity, which increase with the age. As the animal grows older their preferred feed particle size increases. This can provide an opportunity to improve growth response if the most favorable pellet size for different age periods of the animal is identified.

Small pellet diameters could be beneficial during the starter period and on subsequent performance. Larger pellet diameters was suitable for the larger diet because these animals became accustomed to a larger pellet size.

But there are many different kind of animal farming, include poultry, livestock, fish and pet etc, they have different eating hobbit. Not all types of animals need to be feed pellets to the same size.

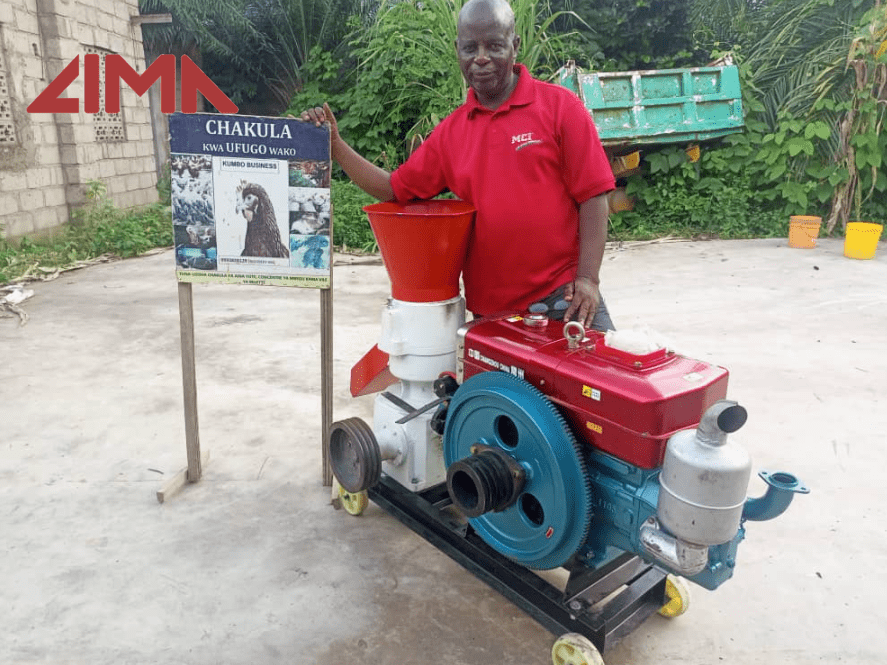

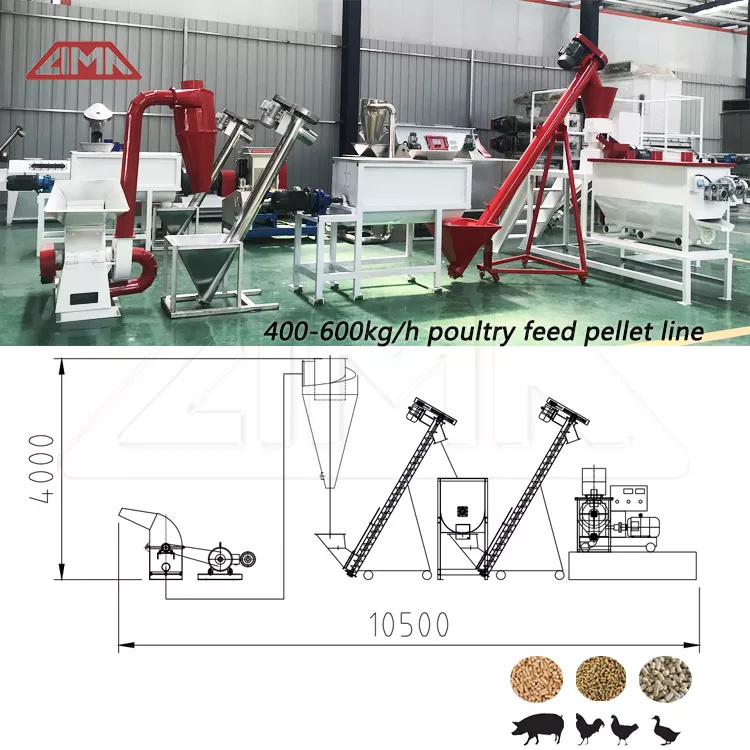

What’s the best pellet size for poultry, like chicken, duck? So you can see the chicken feed pallet machine in lima.

The optimum particle size for broilers is influenced by the feed form, age and sex of the animal, its state of health and the raw materials used. Due to specific abilities of the beak to tactile perception, chickens prefer to pick coarse particles.

For young chicken, finer granulation is required, due to their still underdeveloped digestive system. The provision of crumbled feed is recommended in order to achieve higher feed intake,it can improve nutrient absorption in young animals, also avoid segregation and minimize feed wastage. In the first 6 weeks, 1-3mm powder is generally used.

For the large chicken, the feed should be 2-4mm, the farmer should take care of different period. Like chicken before the litter, the feed should include 2-4mm stone powder pellets, so as to ensure the quality of eggshell.

Although finer particle size is thought to improve digestive quality, it will markedly increase energy consumption during milling. It will increase diet costs of chicken.

Indian research at CCS Haryana Agricultural University investigated the effects of five different particle sizes (2–6 mm pellet size ) in broiler feeds. General conclusion was that feed particle size resulted from the 5mm was most efficiently utilised by the broilers, as it resulted in improved FCR, reduced electricity consumption for grinding and better body weight gains in birds.

Welcome to lima to see the animal feed pellet machine.