Wood pellet machine for sale,making biomass,sawdust pellet

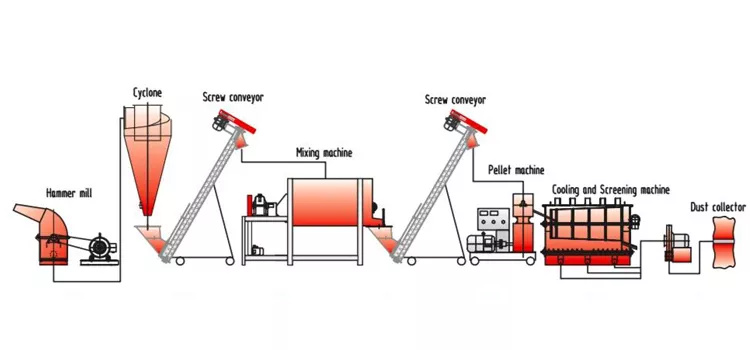

Lima series wood pellet machine can press various kinds of materials into high density wood pellet like branches, wood chips, sawdust, straw, rice husk, barks, crop stalks, etc. Which is widely used in the power station, wood factories, feed factories, toy factories, chemistry factory, power stations, feed factories, fuel plant.

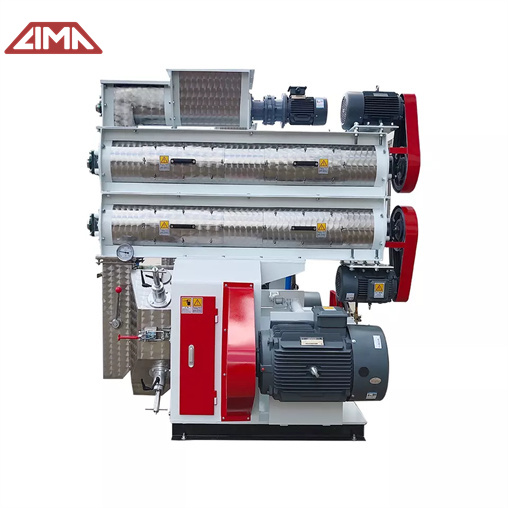

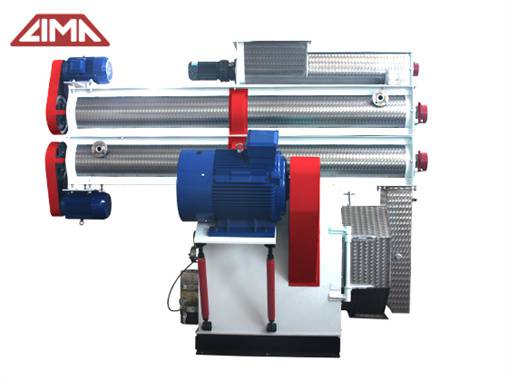

This sawdust pellet machine is featured with compact structure, elegant appearance, high output, low electric consumption, simple maintenance, and convenience to operate. Besides, in order to make different feed pellets to different animals, various aperture or mold can be chosen according to their own requirements. It is designed with flat die and has been equipped with overload protection device, which allows easy and safety operation.

Why are we making wood pellet?

Due to the shrinking of oil resources and the increasingly serious problems of global warming. To relieve the energy crisis, biomass energy is highly advocated all over the world. Wood pellet is a kind of high-efficiency, clean renewable energy source. Wood pellets are characterized by low moisture content, high bulk density, high calorific value and high quality.Moreover, its ash after burning can be used as fertilizer.

Wood pellets are the alternative fuel of the non-renewable energy source like coal, fossil oil, natural gas, etc, which can not only save energy but also reduce the carbon elimination. Wood pellet fuel industry has developed rapidly in the last decade, under the attention of the international community and governments around the world.

Advantage of biomass pellet

Wood pellet machine can makes pellets from rice husks, straw, groundnut shell, alfalfa, grass, sawdust, wood chips, wood shavings and other biomass materials.They are most common and economical raw material to make pellets, which is very easy and cheap to collect.

High heat value

The heat value of the sawdust pellet can reach 3700 to 6300 large cards by adding different chemical formulations, the effect is the same as coal.

Easy to store and use

It takes about more tons per cubic meter, which is less land, convenient transportation and storage. The rural and urban residents canpurchase it in bag, it’s hygiene and easy to use.

Long burning time and easy to ignite

Only a few minutes can ignite. The wood pellet is produced by different formulations, its burning time can reach 2 to 4 hours.

Environment friendly

Biomass energy is renewable, clean, green and environmentally friendly. After the production processing, the pellets contain less water and are denser than logs. It ensures that during the burning, wood pellets release less carbon dioxide to the atmosphere than just burning logs. That is to say, pellets produce less ash and less smoke.Moreover, its ash after burning can be used as fertilizer.

Which raw materials can be used to make wood pellets? Forestry Waste: such as sawdust, waste wood, branches,bamboo, etc.

Agricultural Waste: such as crop straws, cottonseed skins, rice husks, peanut shell, bagasse, weeds, palm kernel husks, etc.

Construction Waste: such as waste paper, wooden frames, wooden templates, pulverized coal, etc.

The biomass pellet machine can make a variety of raw materials into pellets. Its diameter is generally 4/6/8/10/12mm, and its moisture content is 10-15%.

Features of wood pellet machine1.Strengthened high-chromium alloy and heat treatment is used for main working parts, so sawdust pellet machine performs higher efficiency, stability and low noise,extremely well in making hardwood pellets.

The main driver utilizes high precision gear transmission instead of belt transmission to increase 20% efficiency.

Feeding vertically, free of arch of the raw materials, easy for the heat emission in pelleting room.

Die fixed while rollers rotating, producing much higher presion, and materials are centrifugal,evenly distributed around, improving production capacity and also assuring pellets hardness and density.

Maybe you can come to lima to go to see the wood pellet machine.