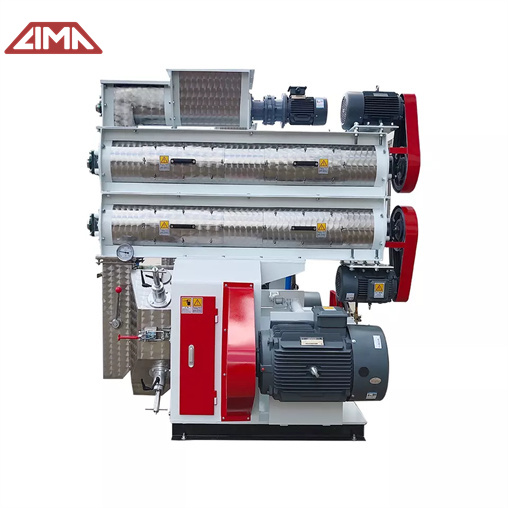

Wood pellet production line,ring die pellet machine for sale

Wood pellet production line can turn various raw materials into high quality pellets, including sawdust, miscellaneous wood, scrap wood, straw, peanut shell, grass, etc. Wood pellets have high density and low moisture content, and they can release long lasting energy. They are easy to ignite, and after burning, they produce little ash for easier cleanup.

Moreover, their burning ash can be used as fertilizer. Wood pellets are a kind of clean, green and renewable energy. Besides, they are a much more cost-effective choice than propane, standard electricity or kerosene, and they are far more environmentally friendly than firewood. Therefore, their demand is increasingly expanded.

Application Of Wood Pellet Production Line

Lima brand wood production plant are used to make biomass pellets for fuel. The most frequently seen raw materials are wood, sawdust, bamboo,EFB (palm fiber), coconut shell, bagasse, agricultural waste, etc.

Advantage Of Biomass Pellet Plant

1.This wood pellet production line can according to customer’s requirements to realize intelligent control, a key type operation, the operation parameters can be automatic control, the production line running is always in the best condition, ensure the production capacity and product quality.

2.It’s widely application to a variety of materials, modular structures, optimize configurations, ensure production lines broad applicability.

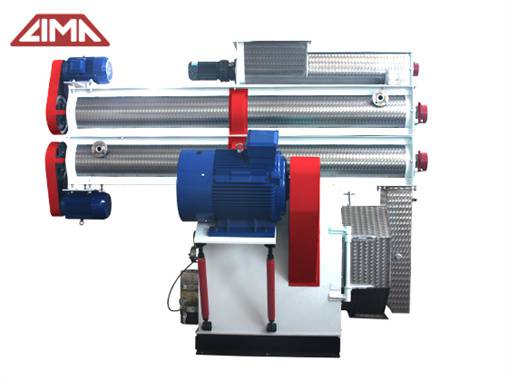

3.Main gear and pinion shaft adopt the carbonizing quenching with high accuracy; smooth driving,low noise and long service life.

4. The imperative feeder device used in the wood pellet production line, which making the biomass pellet production line operate smoothly as the material like wood sawdust, corn, wheat, and rice straw is very light, so they are needed to be pushed into pelletizing chamber by force.

5.The internal structure of the dryer with various efficient feed device combination modes, it effective regulation of drying process and heat distribution, high heat utilization, waste gas discharge temperature is lower than 50 ¡æ, all of designs ensure the production line running low energy consumption.

6. Cost saving. The cover area reduce 50% than the traditional drying granulating production line , civil investment reduce about 50%.

7. Modular dust collecting and purifying heat recycling configuration, safe and protect environmental.

The wood pellet manufacturing process must be in strict accordance with the standards for pellet fuel production, from raw materials selection to crushing, from crushing to drying, from drying to pelletizing. Every step is very important and must strictly enforce standards. Only this can ensure high yield of pellet fuel production. If the crushing is inefficient, the wood pellet produced will be rough. If moisture of drying can¡¯t meet the standard, the pelletizing process will be affected and cause lower output.

This biomass pellet plant is combined with crushing, mixing, conditioning, pelletizing, cooling and other functions. It can produce both biomass pellets and animal feed pellets. so it can satisfy the needs of different users and also the BEST equipment to own your own business in biomass pellet manufacturing industry or animal feed pellet making industry.

Flowchart of Biomass Pellet Production Line

Wood Crusher ¡ú conveyor ¡ú large dryer (not necessary if the raw material has a 12-18% moisture content) ¡ú elevator ¡ú silo ¡ú ring die pellet mills ¡ú large cooler ¡ú finished products warehouse ¡ú automatic packaging machine.

Wood pellet plant is our latest multi-functional biomass pellet production line that is designed and developed on the basis of integration of advanced foreign technology and through full understanding of the users’s multi-level demand. After being selling on the market, it is welcomed by many European and American customers due to its superior performance and user-friendly operation.

The wood pellet production line capacity is from 1ton/h-6tons/h, if you need larger capacities, we can design several lines together to meet your requirement.

Come to Limapoultrymach for a look.