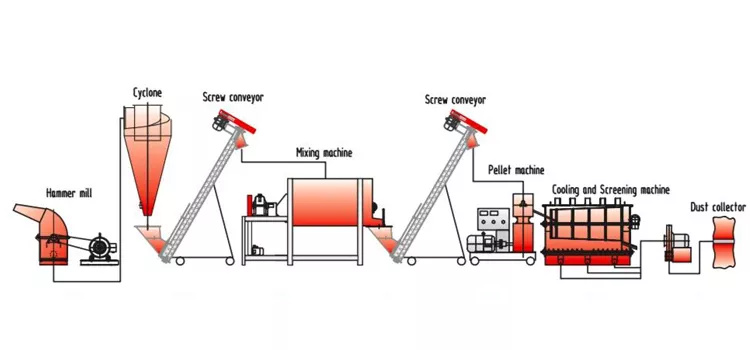

Working principle of the mixer machine

The horizontal twin-shaft ribbon mixer is used to mix dry and powdery materials for the purpose of mixing evenly. During mixing, the material in the material is moved by two rotors moving in opposite directions, and performs a compound motion. The double-shaft paddle drives the material to rotate in two clockwise and counterclockwise directions along the inner wall of the machine groove. Pushing from the inside to both sides, the outer screw drives the material close to the cylinder wall to rotate the axis, and the axial direction is pushed from both sides to the inside, resulting in convection circulation and shear mixing in the material cylinder, completing the rapid and uniform material in a short period of time. mix.

Features:

- U-shaped barrel structure, stable operation, uniform stirring, no dead angle, clean discharge, and wide application range.

- The inner and outer double-layer ribbons are staggered and mixed back and forth, with fast mixing speed and high uniformity.

- Bearings are at both ends of the mixer, the material is not easy to enter, and the maintenance rate is low.

- The screw conveyor is convenient for feeding, the feeding port is flush with the ground, and the feeding is labor-saving and convenient.

- The internal structure and overall design materials have passed the ISO9001 international quality system certification.

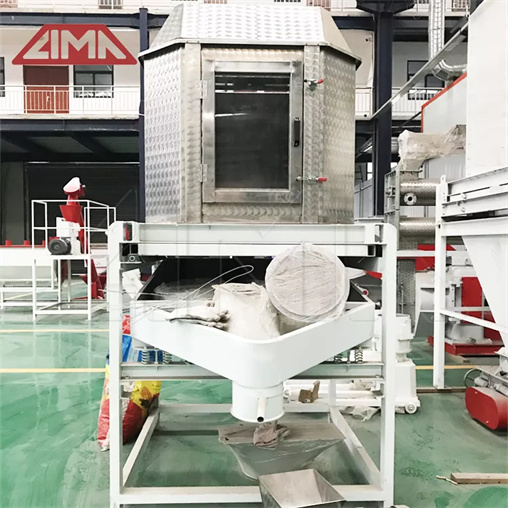

Come to see the chicken feed mixer machine in Lima.

Working principle of horizontal double shaft ribbon mixer:

The machine consists of two parts: feeding and stirring.

- Feeding part: It enters from the feeding hopper, and the material is lifted into the mixer through the screw blade and enters the mixing drum for stirring and mixing.

- Mixing part: When the material enters the mixing drum, it performs a back-and-forth staggered movement, and the mixing effect is good.

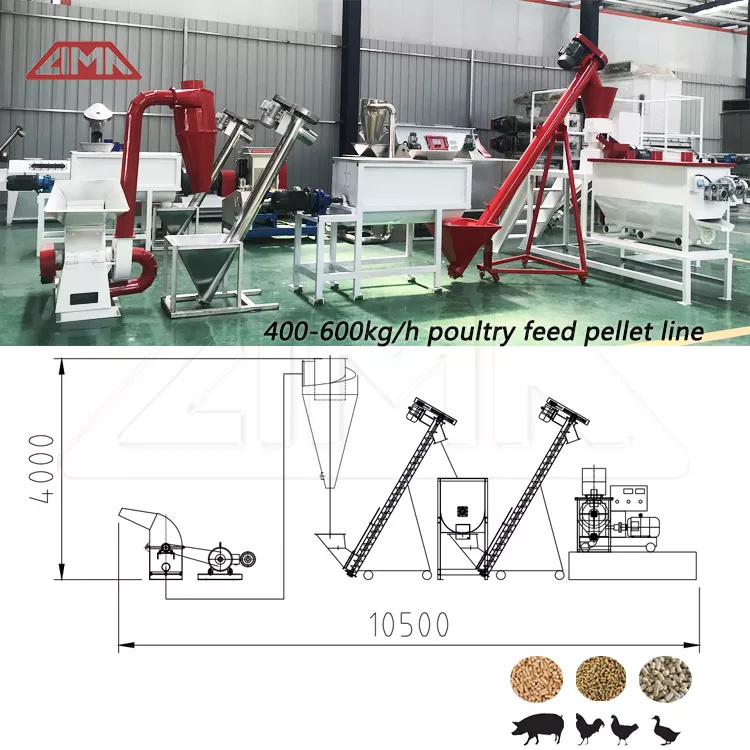

Welcome to limapoultrymach to learn about the animal feed machine.